Perfume Making, Uncategorised

How to Combat Cloudy Dilutions in Perfume Making

How to Combat Cloudy Dilutions in Perfume Making

Achieving crystal-clear fragrance formulations with ease

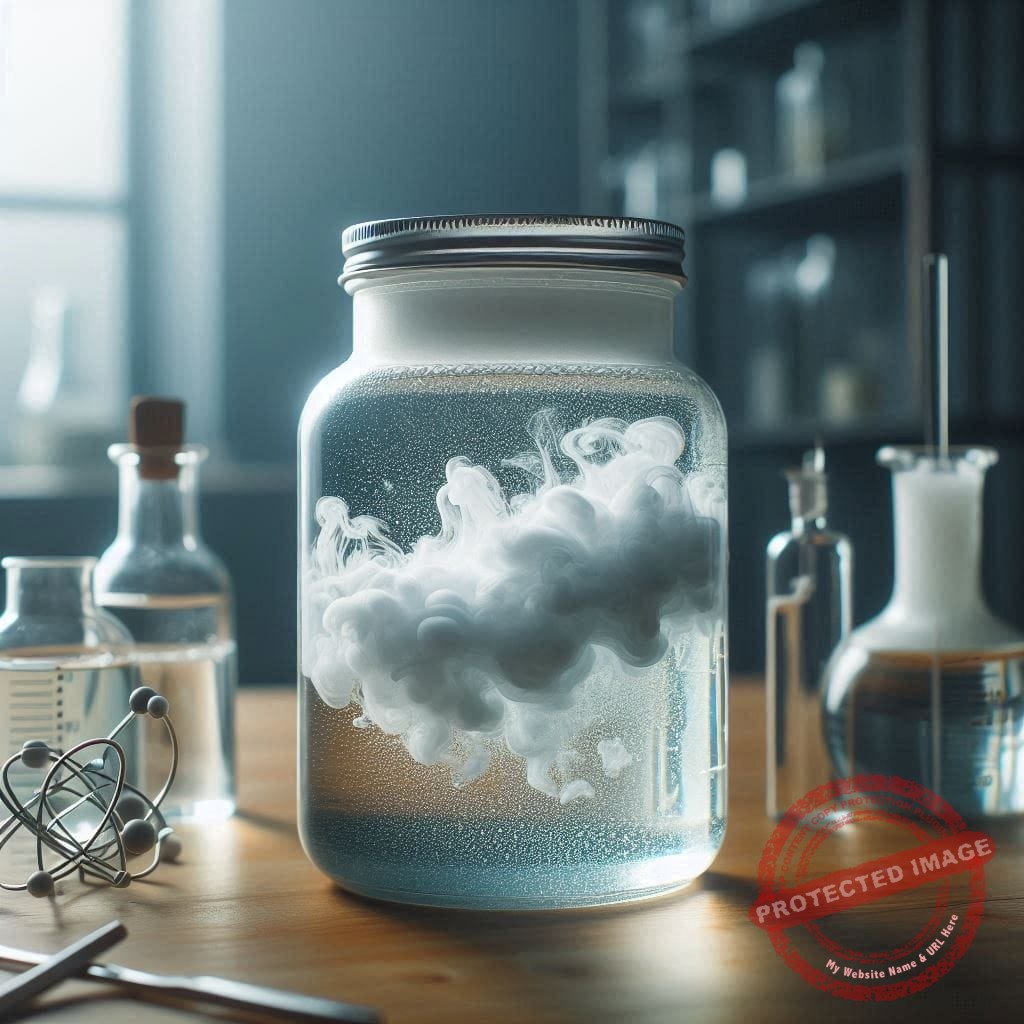

One of the most common and frustrating issues that perfumers face is cloudy dilutions.

You’ve measured your ingredients carefully, followed your formula, and yet… the final solution turns cloudy instead of clear.

Whether you’re crafting a fine fragrance, a cologne, or a functional scent product, cloudiness can signal solubility problems, formulation imbalance, or even poor ingredient compatibility.

Let’s explore what causes this issue and how you can look to address it.

What Causes Cloudy Dilutions?

Cloudiness in perfume usually results from incomplete solubilisation of essential oils, aroma chemicals, or absolutes in the alcohol base. Some of the most common culprits include:

-

High water content in the base, which disrupts solubility.

-

Ingredients with low solubility in ethanol, such as resins, some musks, or fixatives. Some materials are simply not as easy to dissolve as you might think. This includes essential oils and aroma compounds. For example, terpenes, such as Myrcene, are not easily soluble and can become cloudy when mixed with certain carrier oils or solvents, especially at lower temperatures and particularly where the carrier contains an element of water. Polymerised and/or oxidised materials can also be difficult to get into solution. You can tell if your material is subject to this if it has gone from being a liquid to a solid or the liquid form contains clumps, debris or white deposits that were not there originally. Lillial and Bourgeonal, along with the rest of the aldehydes are susceptible to polymerisation and oxidisation and so its suggested to dilute such materials to extend the shelf life as soon as is practically possible. Ambroxan will also solidify in dilutions of 10% or higher, but this is completely normal and should not be confused with polymerisation or oxidisation.

-

Improper ratios of alcohol to perfume concentrate.

-

Temperature changes causing certain materials to precipitate. Cloudiness can be exacerbated by low temperatures. As the mixture cools, components can separate or become less soluble.

-

Using denatured alcohol that may contain additives affecting clarity.

-

Mixing Method Insufficient or uneven mixing can lead to localised concentrations of the material or carrier oil, causing cloudiness.

Solutions: How to Prevent and Fix Cloudy Perfume

- Use High-Purity Ethanol (95-96%)

Start with high-proof, perfumer-grade ethanol. Lower alcohol content increases the likelihood of cloudiness, especially with oil-heavy formulas. - Add Ingredients in the Right Order

Some ingredients are more soluble when diluted in alcohol first, rather than being mixed into a concentrate. Try pre-diluting difficult components before combining them with the full blend. - Check Your Ratios

A general guideline: -

EdP (Eau de Parfum): 15–20% fragrance concentrate to 80–85% ethanol

-

EdT (Eau de Toilette): 5–15% fragrance to 85–95% ethanol

If your concentration is too high, you may exceed the solubility limit of some ingredients, leading to cloudiness.

A higher concentration of carrier oil can help to better dissolve terpenes and prevent cloudiness. For example, try using a 0.1 – 1% concentration in the final product when working with Terpenes. - Homogenisation

If available, using a homogeniser, vortex mixer, sonicator or a similar mixing device can ensure thorough and even distribution of the solution and carrier oil, preventing localised cloudiness. - Cleanliness

Ensure the carrier oil and any other ingredients used are free from contaminants or particles that could contribute to cloudiness. - Use a Solubilizer (with Caution)

Natural or synthetic solubilizers (e.g., polysorbate 20, PEG-40 hydrogenated castor oil) can help emulsify problematic ingredients—but they may also affect clarity or longevity. Use the minimum necessary. - Chill and Filter (“Cold Filtering”)

After macerating your blend:Place it in the freezer (-5°C to -10°C) for 24–48 hours.Use a fine paper filter (like a coffee filter or lab-grade paper) to remove any precipitates.

This helps remove undissolved particles and waxes that contribute to haze. - Test Solubility in Advance

Before finalizing a formula, test small dilutions of each ingredient in ethanol. This identifies solubility problems before they affect an entire batch.

Pro Tips

-

Add water last (if at all). Water is often used to adjust strength or evaporation curve, but too much can cause cloudiness and make sure to use only de-ionised or distilled water, not the stuff direct from the tap!

-

Use only compatible fixatives and bases. Some natural resinoids or thick essential oils may need special handling or pre-dilution.

-

Label cloudy batches and let them sit. Some materials take time to fully dissolve. What’s cloudy today might be clear in a week.

Final Thoughts

Cloudy dilutions are not necessarily a sign of poor quality; but clarity is often equated with craftsmanship and stability in the eyes of customers.

By understanding solubility dynamics and using best practices in formulation, you can effectively address cloudiness in your dilutions and consistently produce beautiful, crystal-clear perfumes. That aside, sometimes, SDA 200 Proof Alcohol is the only way…